Many rolls are pre striped allowing installers to keep a straight line when applying roll strips to the roof side by side.

How many inches does roofing paper need to overlap.

Therefore a 2 inch overlap provides redundancy at the edges where the barrier is weakest.

Overlap seams on the same row 6 in.

All drip edges along roof eaves valley liners and flashing need to be installed before the roof paper layer is laid down.

The overlapping felt creates a secondary barrier for moisture and wicks water away from the shingles above and the sheathing below.

Buy about 10 percent extra.

How to install roofing felt.

Roofing felt is required to overlap 2 inches over the lower felt course.

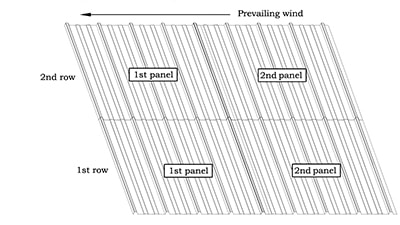

If lap sealant is used simply apply a bead of sealant on top of the underlap ridge going all the way down the length of the ridge before the overlap ridge of the next panel is placed on top.

The answer is the number of square feet of roofing tar paper you need to purchase.

Overlap the seams by 5 inches.

Practice on a couple of 10 ft.

Also place a nail 2 inches from each end of the shingle in line with the other two.

Roofing felt also known as tar paper is a roll of felt coverage is often used when constructing a roof.

Roofing felt is sold by the roll.

Sections until you get the hang of it and don t roll out a 25 ft.

But as with so many other projects the key lies in the prep work.

It is commonly called 15lb paper.

Once you understand what it does and you know which one you need you are ready to lay the underlayment for your roof.

The most common size width for rolls of roofing paper is 36 inches.

Each row of paper should overlap the one below it at least 2 in.

Adjacent pieces of drip edge should overlap at least 2 inches 51 mm.

How many rolls of felt will you need.

In order to know the appropriate amount of roofing felt to use the roof pitch will need to be calculated first.

However make sure that you do not nail into the tar strip.

It provides extra waterproofing to protect the wood until shingles are installed.

The vertical leg of the drip edge should be at least 1 5 inches wide and extend at least 0 25 inches below the sheathing.

Section of paper on a steep roof or when it s windy.

A typical bundle of shingles weighs about 75 pounds while some premium products can weigh over 100 pounds per bundle so consider delivery of materials.

If you take the time to properly prepare the roof then laying the felt will be easy.

In all use four nails per 3 tab shingle.

There will be overlap lines printed on the paper to guide you.

In other words if the height of the roof drops by 2 inches for every 12 inches in length you will need to use sealant to strengthen the overlap barrier.

The average roll of 15 pound roofing felt covers about 400 ft 2 or 4 squares while the average roll of 30 pound.

You can usually return it if you don t need it.